As the cosmetics industry faces the dual challenges of 'high-variety, low-volume' production and 'zero-defect' requirements, traditional rigid production lines have hit their performance ceiling. According to data from the International Cosmetic Manufacturers Association (ICMA), over 60% of global cosmetics enterprises will prioritize flexible production line retrofitting as a strategic initiative by 2025, with penetration rates of flexible automation equipment in the cosmetics sector projected to exceed 42%.

On May 12, SRT, as the first domestic enterprise to achieve the industrialization of soft robotics technology, debuted its innovative architecture of 'hyper-flexible technology base + daily chemical scenario modules' at Booth E31, Hall N5 of the 29th CBE China Beauty Expo, providing the industry with a full-stack solution from single-point component handling processes to entire line upgrades.

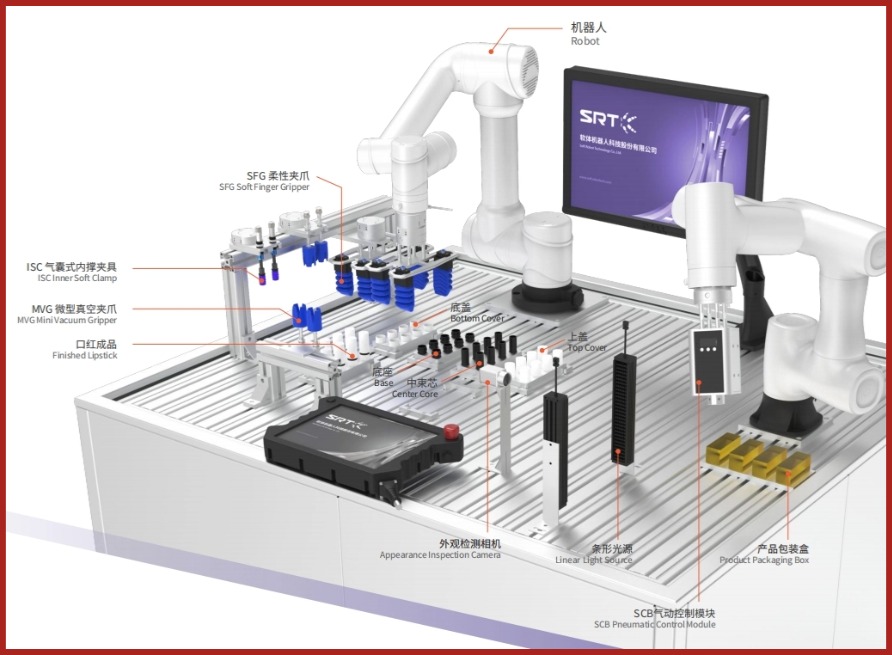

In the field of precision component handling, SRT's self-developed bionic grasping technology has achieved scaled industrial application. Its multi-series Soft Dexterous Hand products, developed based on bio-inspired mechanisms from nature, utilize a micrometer-level polymer-silicone integrated molding process to achieve repeat positioning accuracy of 0.01-0.08 mm. Taking lipstick tube precision assembly as an example, SRT innovatively employs a single-station, dual-gripper collaborative operation mode. Through high-density array layout design, it maintains a high-speed cycle rate of 130 cycles per minute while achieving a daily production capacity of 30,000 units (representing a 400% increase versus conventional solutions), with industry-leading metrics of changeover time under 15 minutes and damage rates below 0.01%.

Exhibition Solution | Integrated Lipstick Assembly & Packaging Appearance Inspection Solution

System Architecture | Lipstick Hyper-Flexible Assembly Workstation

Packaging Box Appearance Inspection Workstation

Solution Advantage | SFG/ISC/MVG Multi-Modal Gripper Collaboration

Collaborative Robot Cooperation

Open Vision Platform with Fusion Algorithm Engine

Modular Scalable Design Architecture

Performance Metrics | Expansion/Gripping Dual-Mode Operation for Multi-Specification Lipstick Tubes

Precision Non-Destructive Assembly with 99.9% Yield Rate

Fully Automated Inspection of Transparent Film Wrapping on All Six Faces of Packaging Boxes

Extended Applications | Luxury Lipstick Gift Sets / Skincare Outer Packaging / Color Cosmetics Kits

Cross-Industry Rapid Replication Capability

In quality inspection and packaging operations, SRT innovatively adopts a 'Modular Design + Intelligent Collaboration' technological architecture, delivering end-to-end automation solutions for cosmetics spanning from boxing, inspection to finished product output. For instance, SRT's flagship packaging line—the Transfer Robot Application Platform—adapts to 80% of irregular packaging specifications, boosting production efficiency by 200% compared to conventional methods. Particularly in the integrated lipstick assembly and packaging inspection solution, the system achieves 99.92% defect detection rate for film wrinkles, ruptures, etc., with merely 0.3% false positives through the fusion of a 5-megapixel industrial camera and dual-exposure imaging technology. This demonstrates the profound synergy between machine vision and flexible handling technologies.

SRT's technological architecture demonstrates significant cross-industry applicability. Currently, this technology ecosystem has been successfully deployed across multiple sectors including food, daily chemicals, and warehousing logistics, enabling clients to achieve an average 45% reduction in labor costs and 30% enhancement in production capacity.

Amid the surge in personalized cosmetics demand, SRT is pioneering the implementation of a 'Flexible Gripper as a Service' (FGaaS) model. This approach utilizes standardized interfaces and parametric configuration to enable enterprises to rapidly deploy automation solutions adaptable to diverse product lines. During the CBE Expo, SRT's technical team will conduct in-depth technical sessions at Booth E31, Hall N5 of the Shanghai Beauty Expo, sharing implementation experiences from flagship industry projects. Industry peers may schedule tailored solution diagnostics via the official website.

Contact Person |SRT softrobottech

Tel: +86 186 5112 5686