In the 3C electronics industry, enterprises are seeking the best cost solution because of the variety of products and the fast speed of iteration. As a pioneer of advanced technology, SRT has always been committed to exploring flexible production methods. Next, we will show you the classic application of the 3C electronics industry.

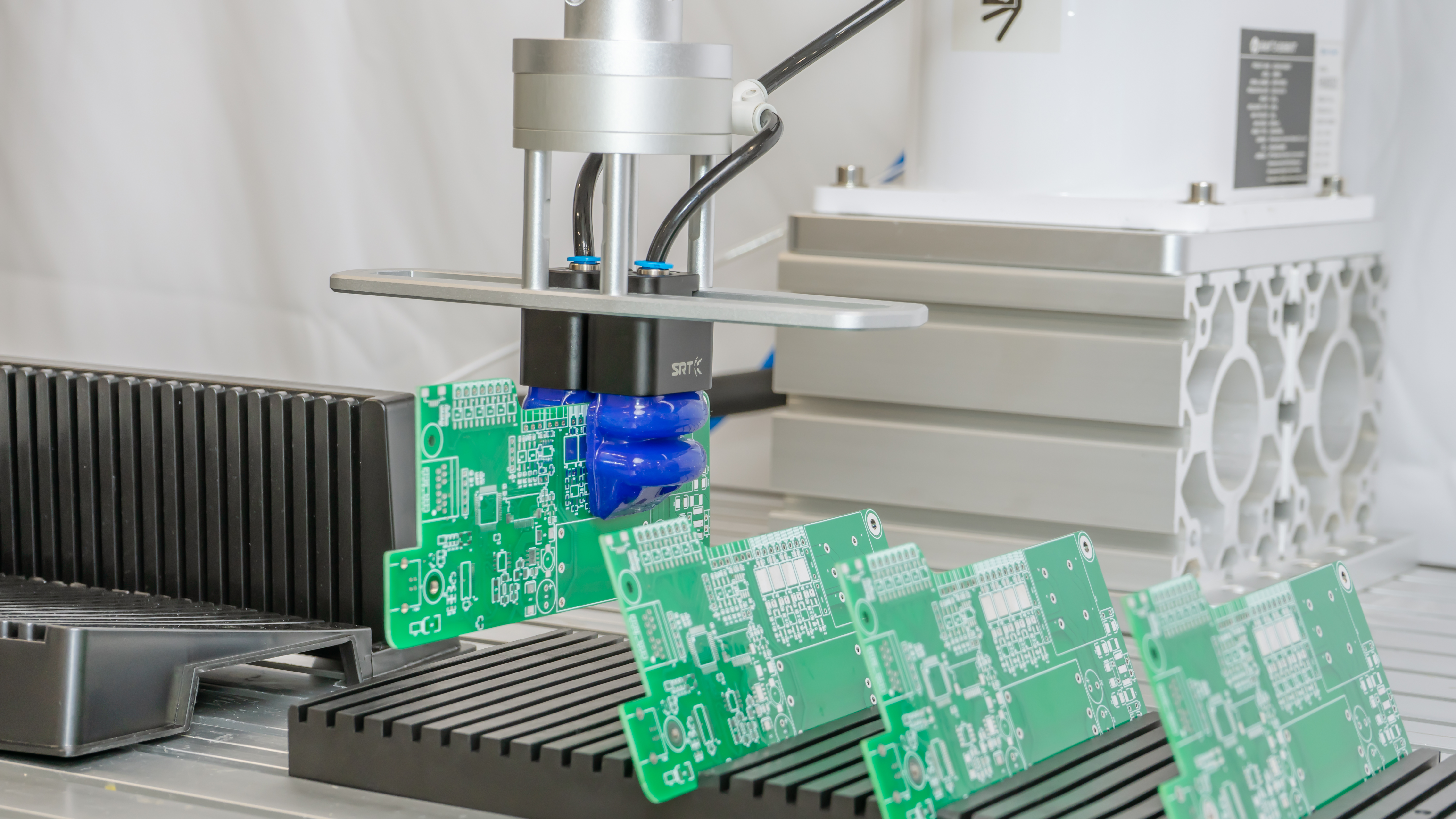

01 Loading and unloading on PCB board

The thickness of the PCB board is only 2 to 0.2mm.Compared with the traditional clamping gripper, the flexible gripper’s clamping force is more flexible and controllable, which can prevent the PCB board from warping and damaging during the process of loading and unloading.

02 Mobile Packaging

In the process of manual mobile phone back packaging, errors in operation or dirty packaging are easy to occur.The flexible grippers of SRT can automate the boxing process of mobile phone and its accessories, and control the product accurately, so that the production line can achieve better human-machine cooperation and improve the product qualification rate.

03 Loading and unloading of electronic components

Electronic components have different sizes and shapes, and high construction precision. In traditional feeding and unloading materials, excessive or insufficient grabbing force may cause damage to components.SRT does not need frequent replacement devices for flexible clamping grippers for electronic components. A "claw" can be compatible with a variety of products, and can effectively guarantee the stability of product quality.

04 Headphone assembly

When the assembly or assembly parts are abnormal and easy to damage, the robot needs to be equipped with flexible and adaptive adjustment of the end fixture.SRT's flexible grippers have flexible adaptability and no need to adjust according to headset size, so that accurate and flexible assembly process can be realized.

05 Visual inspection scheme for screen panel grabbing

Manual detection of screen panels, labor intensity, low efficiency, easy to miss.The flexible grippers can be used to grab the edge of the panel to achieve flexible grasping and intelligent detection of vulnerable panels.The utility model compensates for the visual inspection blind area and the defect of absorbing and leaving marks in the suction tray, which greatly reduces the manpower requirement of the production plant.