At present, intelligent manufacturing has become the core path for my country to realize the transformation and upgrading of the manufacturing industry. In special times, masks, as a medical necessity related to the health of the whole people, require mask manufacturers to not only respond to the market quickly, but also have large-scale industrial automation and intelligent manufacturing production capacity.

Combined with the current market demand, the company launched a new generation of "Comprehensive Solution for Intelligent Manufacturing of Masks", which has been officially put into production. The solution adopts the front-end AI vision algorithm to further optimize the stability of the mask production process while improving product standardization; through the introduction of the MES intelligent manufacturing system, the fully automated control of the mask production process is realized to ensure product quality and thus improve the enterprise Production and operation efficiency.

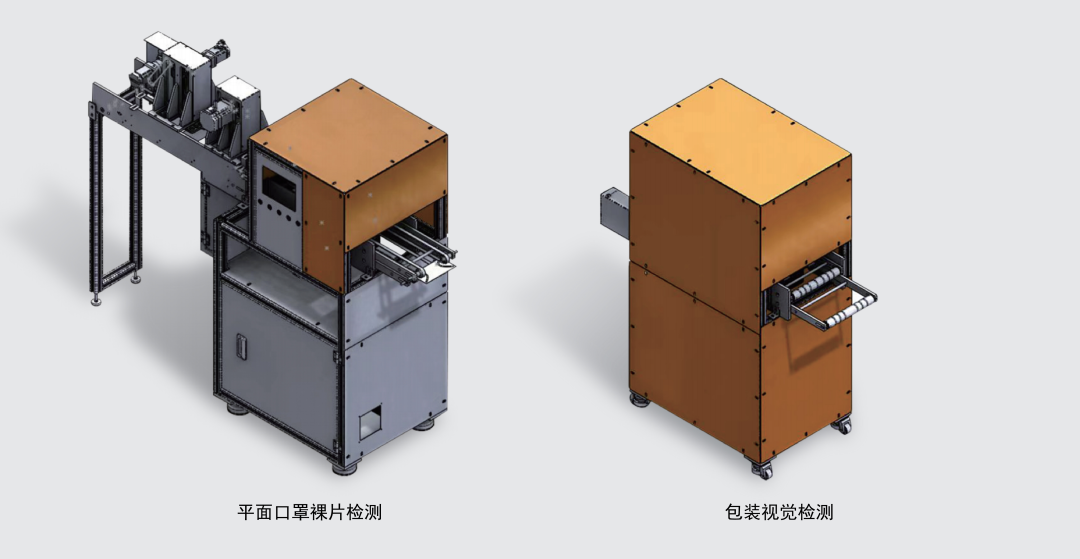

Flat mask bare chip detection | Packaging Vision Inspection

Adopt excellent AI vision algorithm

Machine vision inspection has high speed, accuracy, repeatability, and long-term working stability. Compared with manual inspection, it greatly reduces the error rate and avoids the fatigue-prone defects of human eye inspection, thereby improving product quality and production speed. .

During the detection process, it is not necessary to manually touch the surface of the mask to accurately locate and identify subtle defects, which is equivalent to the speed of simultaneous detection by 4 to 6 workers.

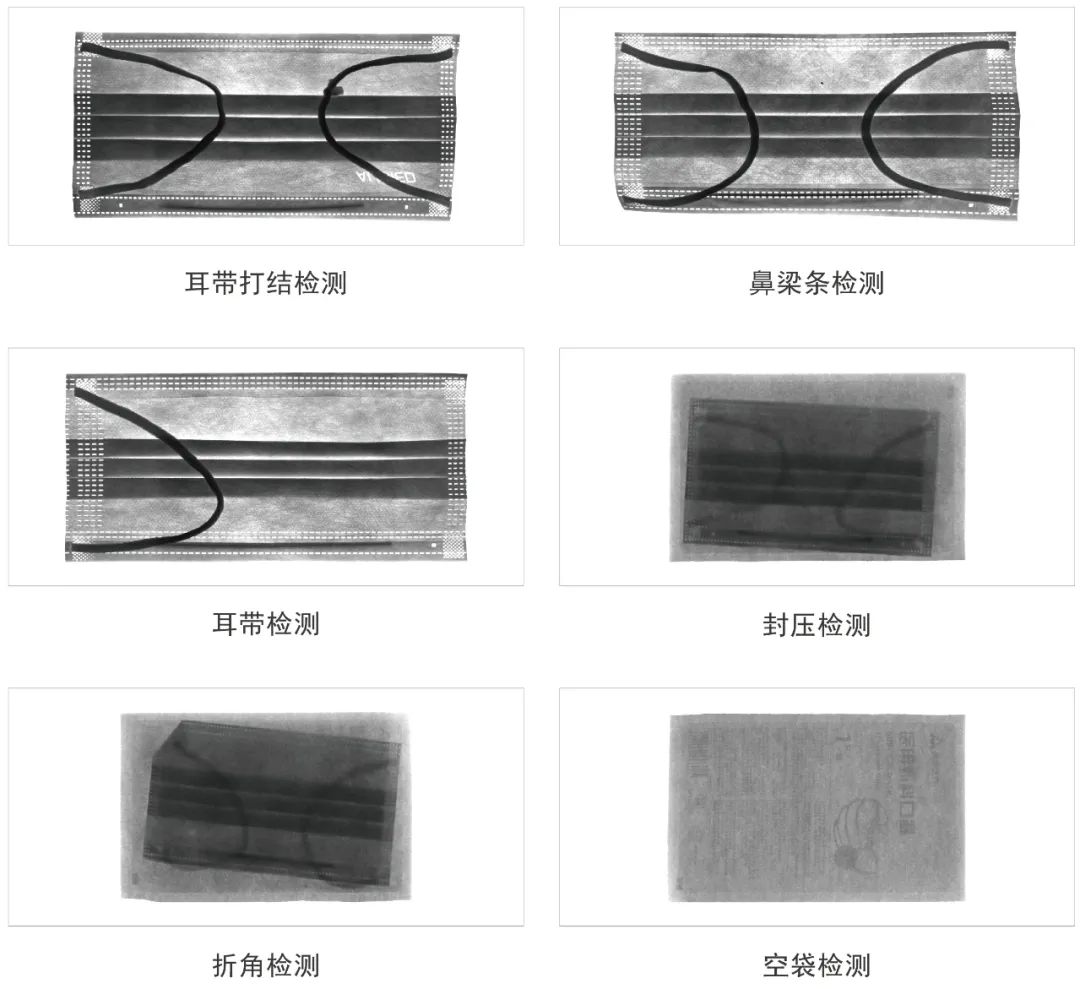

| Test content

Mask bare chip detection content: detection of mask size (accuracy ± 2mm), presence or absence of ear loops, ear loop leakage, knotted ear loops, tape residue, presence or absence of nose bridge strips, dirt and foreign objects on the surface of the mask (hair strands can be detected)

Mask flat package inspection content: edge pressing, poor sealing pressure, empty paper bag, tape residue, folded corners, multiple pieces, dirt and foreign objects, poor printing, etc

After long-term accumulation of this product, AI model training has been carried out on various types of mask bare chips and mask packaging existing in the market, and a variety of detection AI models have been formed, which can realize the rapid landing of new products.

In addition to standard medical mask testing, the company can also provide N95 mask bare chip testing devices and N95 mask vertical bag testing devices.

| Solution advantage

The production efficiency of conventional masks is 200pcs/min, and the highest can reach 500pcs/min.

Use 1 or 2 sets of line-scanning high-resolution industrial cameras and lenses to take images of different defects

Various combinations of customized line-scanning infrared light sources and line-scanning white light sources are used for supplementary light, eliminating the interference caused by the pattern of the mask itself and the packaging and printing of the mask

AI edge server is adopted to increase computing power, thus ensuring the high-speed and stable operation of AI algorithm and traditional visual detection algorithm

Adopt I/O control unit based on FPGA core to ensure stable rejection under high-speed operation

Different from most manufacturers on the market who only use traditional visual detection algorithms, this product uses the combination of AI deep learning detection algorithms and traditional visual algorithms for detection: due to the different sizes and various gray values of the mask surface and mask packaging The pattern changes, and the gray level change of the junction position will have a great impact on the detection of traditional algorithms. At the same time, the diversity/inconsistency of defects is also difficult for traditional algorithms to achieve comprehensive detection. Therefore, AI deep learning is used to cooperate with Traditional algorithms are used for detection together to ensure the accuracy of detection.

The same set of detection device can realize the detection of various mask bare chips or mask packaging, and can realize fast switching, compatible with adult masks, children's masks and various customized masks, paper-paper packaging, paper-plastic packaging.

According to the grading of mask defects, the highest missed detection rate of 3/100,000 and false detection rate of 1% for major defects can be achieved.

MES intelligent manufacturing workstation |

Realize production visualization, standardization, traceability

Through the seamless connection with MES system, the program can realize the production plan management, product quality management, process control management, equipment maintenance and statistical reports of the entire mask production line, so that the whole process of mask production can be monitored, traceable and remotely assisted, and at the same time reduce manual errors.

The mask intelligent manufacturing comprehensive solution can generate wired and offline layouts. From "stand-alone manufacturing" to "wired production", from "labor-intensive production" to "de-artificial development", the scheme successfully uses the contactless detection mode, which not only effectively solves the traditional detection problems and makes the production efficiency higher, but also realizes the leap-forward development of the mask production line to intelligence, information and customization.