Blister tray is also called plastic inner bracket. Generally, the flat plastic hard sheet is heated and softened, placed on a specific mold, formed by vacuum suction, and cooled into a plastic tray with a specific groove. Compared with other types of packaging on the market, blister tray health, environmental protection, low cost, easy to clean, is widely used in electronics, medicine, food and other industries, play the role of anti-static, foil, shock-proof, separation fixed.

01 How Do I Solve the Fragile/Cascading Problem?

Blister tray is usually placed in layers. When in use, due to superposition fastening, and the edge is thin, it is difficult to separate. The traditional claw is difficult to complete the grasping and handling process in the face of the above conditions.

Simulated manual operation

Inspired by the shape of starfish arms, the SFG flexible gripper developed by SRT is able to gently grasp objects under pressure control, as well as achieve complex layered transport.

02 SFG flexible clamp claw application advantages

Precise layering clip

Through the coordination of the pneumatic components inside the controller and the program algorithm, SFG flexible gripper can achieve accurate output of the controller air pressure, the air pressure accuracy can reach ±2kPa, to achieve accurate stratification and handling of the blister tray.

Hold the weak edge without breaking the edge

SFG flexible gripper single finger thrust in the range of 0-25N accurately controllable, will not hurt the tray.

The whole process does not touch the surface

SFG flexible gripper by kneading grab, easy to achieve traceless handling, to ensure that the product surface without defects, improve the yield.

It can grab the tray with large size

SFG flexible clamp claw single finger weight is only 18.9g, using standard modular design, "U" type finger module can be directly locked and installed on various specifications of aluminum profiles, customers do not need to customize large support for different materials, through the profile quickly splicing frame, and then installed on the finger module, you can obtain available fixture, even if the size of the panel is more than 1 meter, It can be carried easily.

Applicable to the requirements of high grade dust-free workshop

Blister tray in the production of equipment cleanliness requirements are very strict. SFG flexible gripper has good sealing and stability, can prevent dust, oil and other infiltration into the fixture inside. At the same time, the flexible jaw has passed the RoHS 2.0 certification and ISO9001 quality management system certification requirements, in the process of customer use, to ensure the quality and safety of equipment, is the perfect choice to adapt to the high-level dust-free workshop.

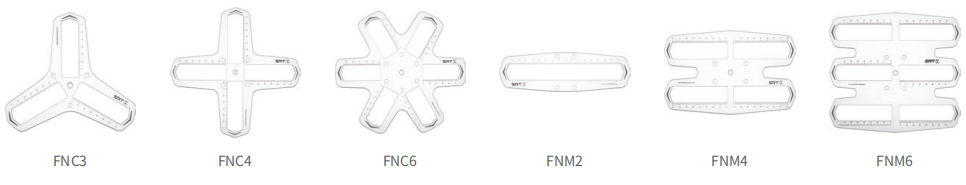

03 All kinds of pallet/box grab model selection

The blister tray on the market has a wide variety of different sizes. Through the repeated trials of SRT researchers, different bracket models can be used to grab the blister tray beyond the standard bracket range, and the production line can be customized according to the actual production situation.

Ordinary blister tray

[Bracket construction] The bracket can be built according to the shape of the blister tray. The circular blister tray can be built into FNC4 cross type when grasping; Rectangular or square blister tray, can be built into FNM4 H type or FNM6 mouth type bracket;

[Finger selection] For lighter weight blister tray, it is recommended to use N30 series fingers, the air pressure value is maintained between 10 ~ 35kPa positive pressure;

If the blister tray is heavy, it can be replaced with N50 series fingers. This series of fingers has rich categories, wide grasping range and mature technology, and the air pressure value can be adjusted to more than 80kPa.

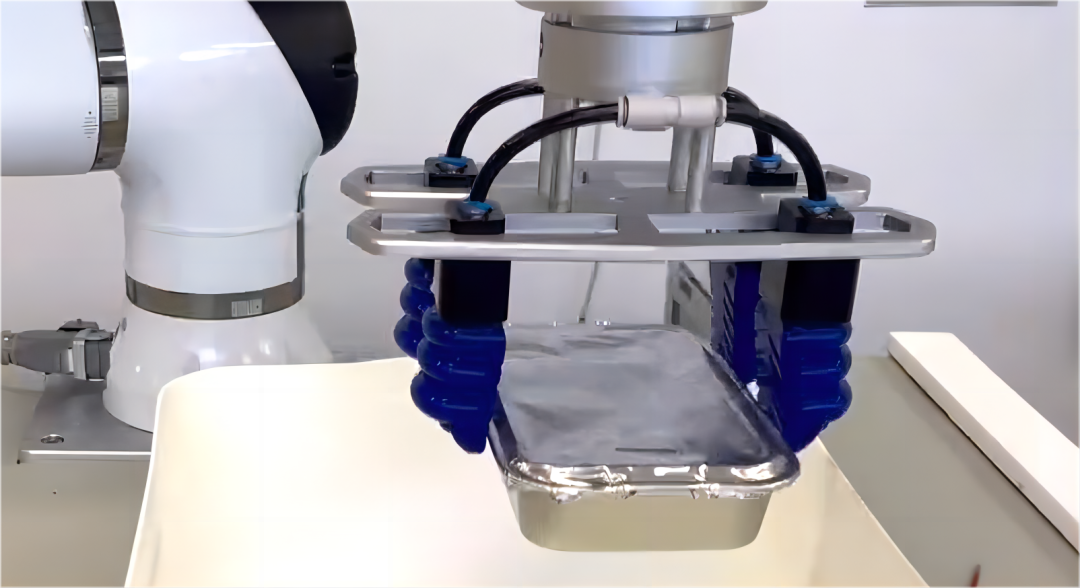

Extension and extension application based on blister tray

SFG flexible gripper can not only grab all kinds of blister trays used in electronics, medicine and other fields, but also carry out sorting and handling of prefabricated vegetable trays and various aluminum foil boxes containing food, such as:

The aluminum foil box is loaded with the same weight of food, and the weight of the box is between 300 and 800g. SFG-FNM4-N4036 and SFG-FNC3-N4036 fixtures are used to grab and move quickly, which can still maintain good stability. In addition, the flexible finger module as a core part of SFG flexible gripper, its material is made of food grade silicone rubber, safe, reliable, high flexibility.

In order to meet the diverse and complex scene needs of all walks of life, SRT will continue to introduce updated products and better services, to help the application of intelligent manufacturing technology more convenient and widespread.