In the past two years, the process of intelligent manufacturing has accelerated. With the continuous improvement of the intelligent level of industrial scenes, automatic tools are bound to develop in the direction of more precision, more integration and more flexibility, and the application field of electric terminal shows more and more space for expansion.

Based on market insight, SRT creatively introduced SCB-IM Terminal Active control module (SCB-IM for short).

As the driving controller of flexible end clamps, SCB-IM takes smaller volume and more optimized structure as the base point to solve customers' pain points such as being unable to start automatic operations due to limited air source or space, and meet the application needs of more scenarios.

【全新SCB-IM末端有源控制模块】

The restriction of external conditions is one of the important factors affecting the development of automation. The new SCB-IM is compact and flexible, with a built-in micro-air pump as a pressure generator, which drives the flexible fixture through the output of positive and negative pressure. It is easy to deploy and can be used in a single machine. It is an ideal choice to cope with market changes.

01 No wiring, get rid of "air source" dependence

Unlike previous pneumatic control modules, SCB-IM is a plug-and-play end-drive module that does not require additional air supply, eliminating 100% dependence on air supply in many operational scenarios. The elimination of air source means more convenient and easier installation, abandoning the bondage of high-pressure air source, pipeline and other external equipment, wiring difficulty is almost zero. The deployment time is short, making it easier for customers to use devices, reducing deployment and maintenance costs.

02 It is light and easy to install the end of the mechanical arm

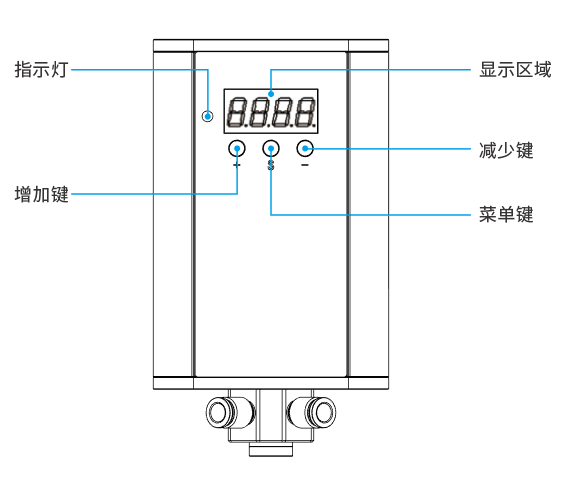

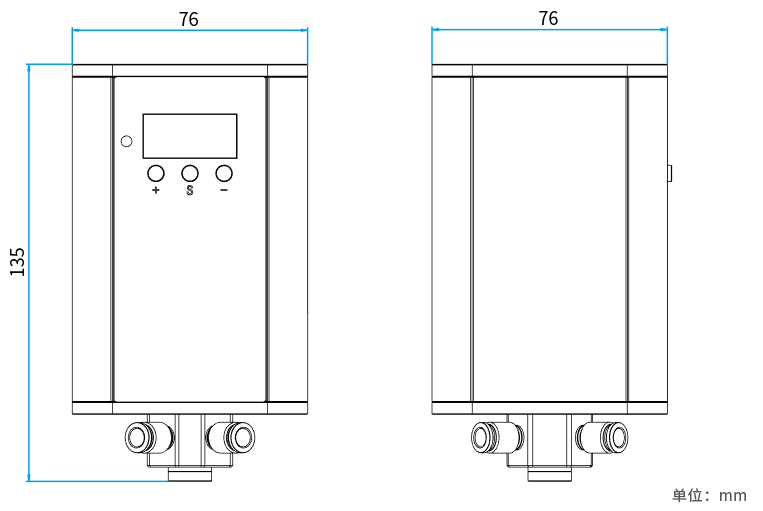

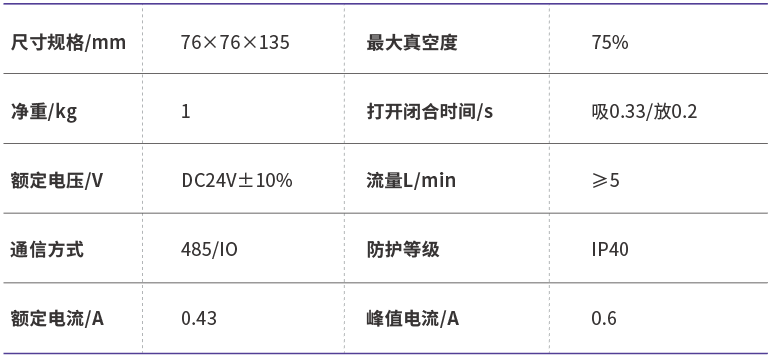

How to highly integrate each product module and apply it in the limited space of automation equipment is a long-term proposition for equipment suppliers. SCB-IM is compact, compact and flexible, with an outline size of only 76*76*135mm, 80% smaller than that of the traditional pneumatic controller. It can be installed at the end of the mechanical arm through the flange interface and become the "seventh axis" of the mechanical arm. Compared with the traditional pneumatic control module, it saves more space, solves the grasping dilemma of compact production space and large equipment footprint, and improves the utilization rate of space.

03 Stronger adaptability, can be used in one machine

Strong versatility is another major product advantage of SCB-IM. SCB-IM not only fits most of the mechanical arms on the market, but also perfectly matches all the flexible clamps of SRT and the common vacuum suckers in the industry. The high compatibility ensures the flexibility and deployment of the flexible end clamps.

In order to help customers achieve full automation of production, SRT continues to increase the development of new products. As the first electric product of SRT, SCB-IM has the following advantages:

A variety of pressure regulation methods

SCB-IM has two modes of manual voltage regulation and automatic voltage regulation. Automatic voltage regulation can meet the operating conditions of automatic control and is extremely flexible.

Wide range of applications

It is suitable for working conditions that cannot provide air source for a short time, such as agricultural picking, AGV handling, unmanned vending shops, etc.

Help customers upgrade

SCB-IM keeps a good cost performance to meet the needs of more diversified product applications, helping customers easily achieve rapid transformation and expansion of production lines.

Data show that the grasping and handling operations completed by the end-effector account for more than 60% of the total number of industrial robot processes. It is an important development direction of SRT for a long time to create "skilled hand" and grasping solutions with soft robot technology as the core for automated production. With the increasing popularity of high-end intelligent manufacturing in the future, SRT will adhere to the product as the core, focus on the future, comply with the trend of intelligent manufacturing and flexible production of enterprises, and create diversified production scenarios for customers. At the same time, it will help accelerate the upgrading of "intelligent manufacturing" in China.