EXHIBITION COVERAGE

Class 108 ·CFDF

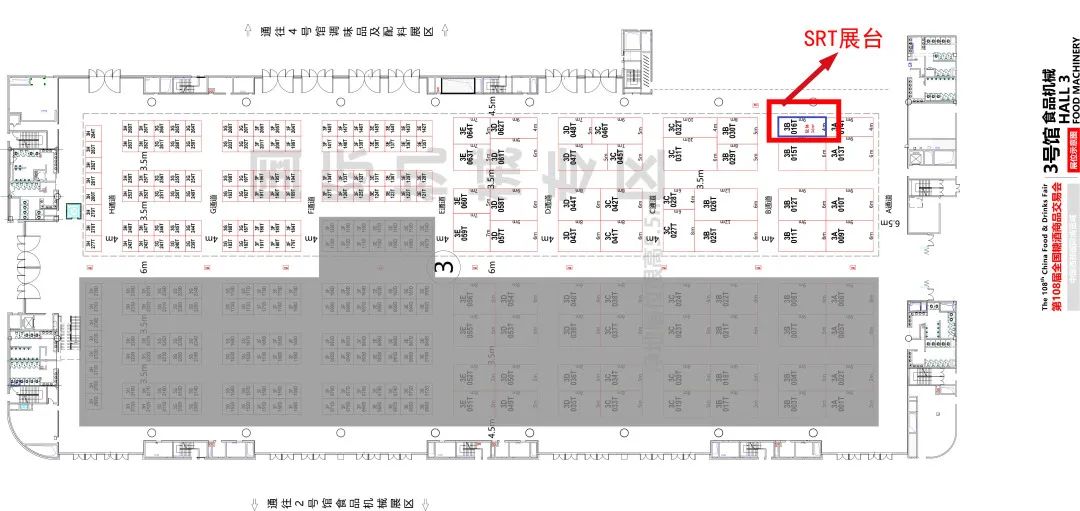

West Expo City food machinery area 3B016T

On April 12th

China's food industry "barometer" said

The 108th National Sugar and Wine Fair

Hot development in Chengdu

This exhibition

SRT brings a double whammy

Full automatic packing visual inspection overall solution

And standard printing and labeling machine

Full display of efficient automated work flow

Themes | national sugar and wine will be delicious

Where | western expo city/century city, new exhibition center

Date | April 12-14

The booth | western expo city - 3 b016t

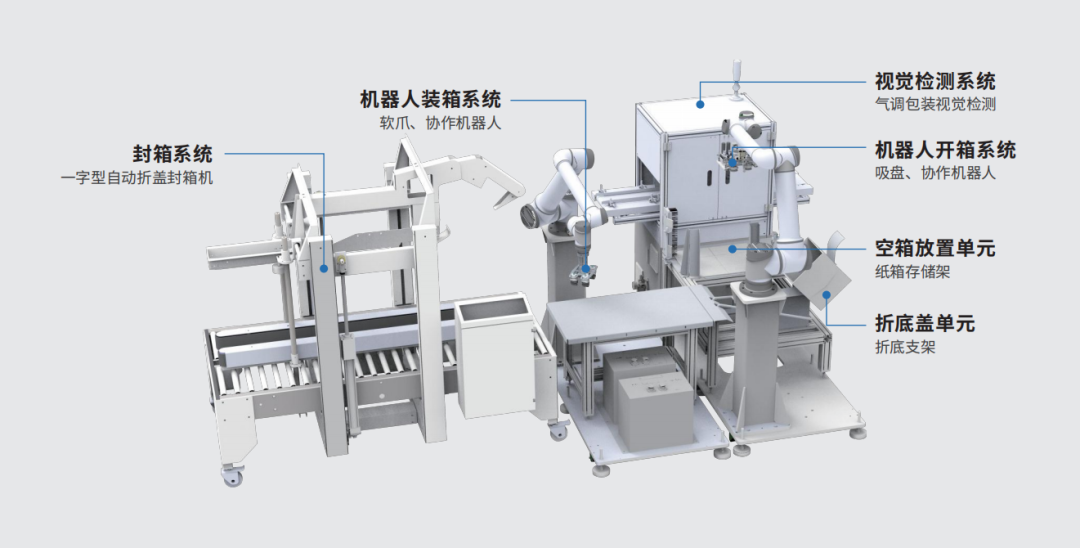

Package | automatic packing visual inspection the overall solution

Other | standard printed labeling machine

Total solution

Automatic packing visual inspection

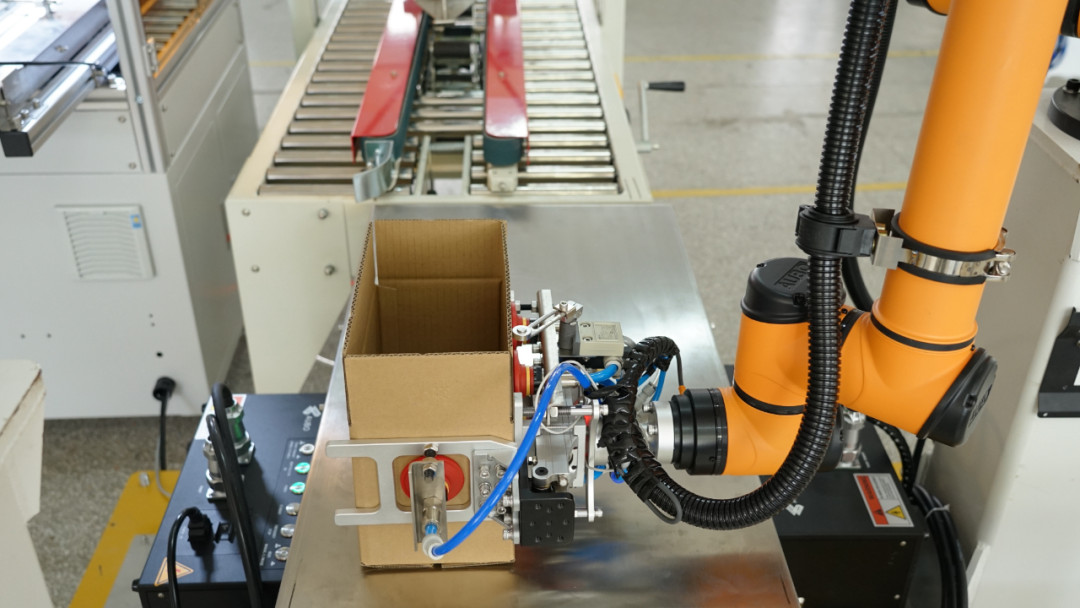

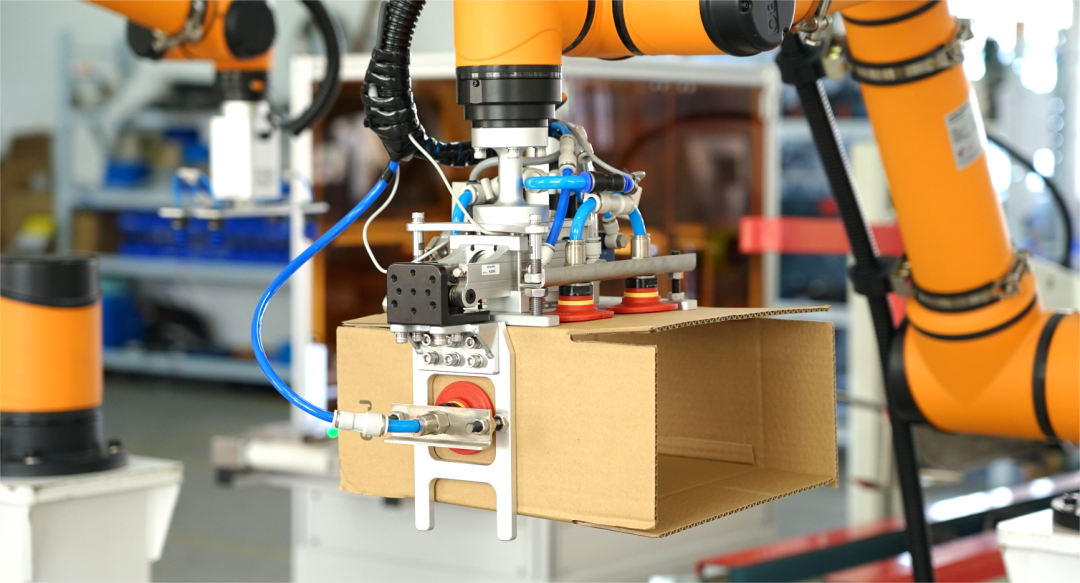

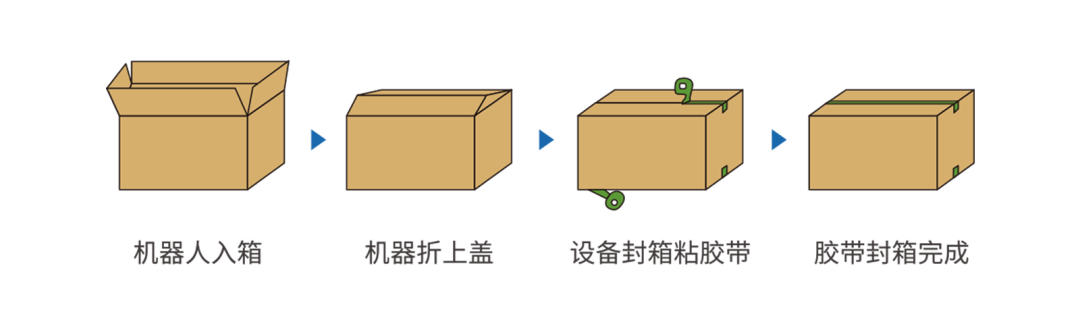

Machine vision flexible jaw automatic unpacking

SRT automatic packing visual inspection overall solution combines machine vision, flexible jaw and automatic sealing machine efficiently, which can realize the one-stop operation of box forming, bottom folding, packing and sealing, with high efficiency and stable quality.

“Carton molding process is widely used in the packaging of goods. Traditional manual operation speed is slow, high cost, easy to produce defects in the process of operation, resulting in quality is difficult to guarantee.

With the rapid development of industrial robot technology, automatic packing scheme based on advanced vision system has become an important starting point to promote a new round of "machine replacement" and improve the advantages of traditional industries.

Scheme advantage

Saving energy and reducing consumption reduces labor costs

The use of cooperative robots can completely replace the manual unpacking operation, to ensure the production line 24 hours uninterrupted production. Compared with labor, each production line can save workers and increase production efficiency by 30%.

At the same time, the average power of cooperative robots only needs 200W, which helps customers truly realize "high-quality, efficient and low-consumption" automatic production and effectively reduces labor costs.

Flexible deployment Adds flexibility to the production line

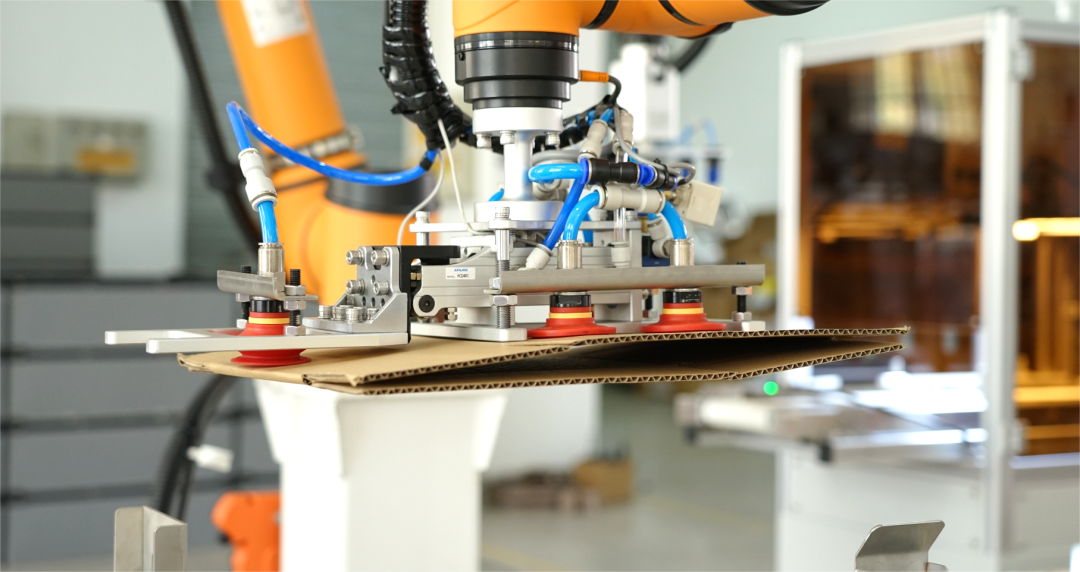

Sex box variety, size difference is large, robot unpacking can meet the multi-specification carton unpacking, without manual repeat debugging. The traditional production line uses the array type product packing, the gap is small, easy to crush the carton when packing. The repeated positioning accuracy of the cooperative robot can reach ±0.02mm, and the placement position is accurate and smooth.

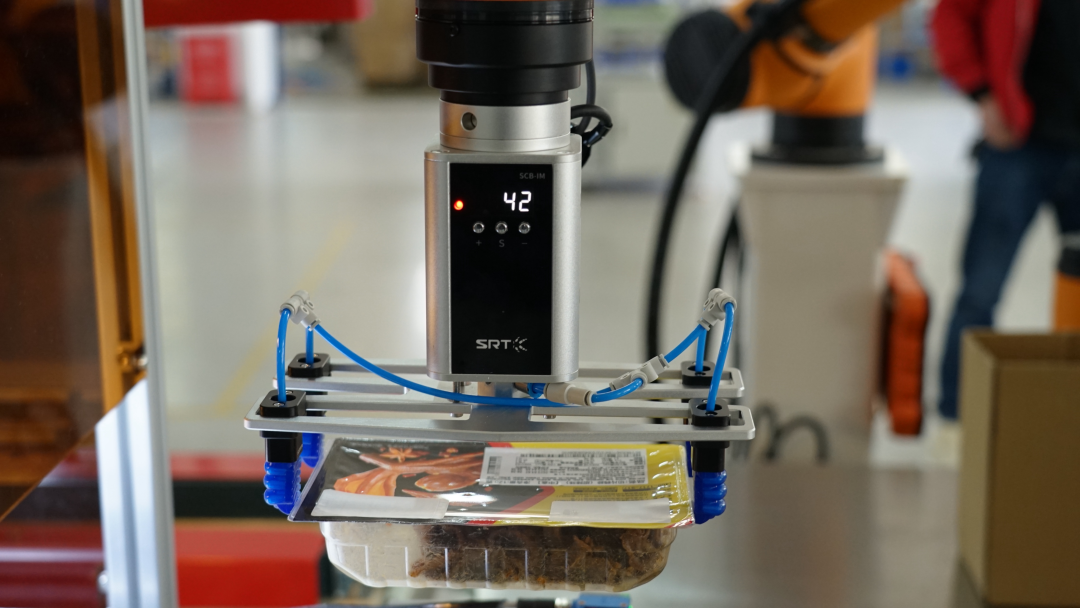

The packing is carried out by means of flexible clamping claw. Based on the characteristics of compact, lightweight and flexible deployment of the opening and packing system, it can be placed in any station according to the needs of the site layout to complete the seamless docking of the existing production line and realize the automatic flexible production.

Safe, reliable and trustworthy partner

The open-box system supports level 10 collision detection, making it possible to share the work space without fencing. Through collaborative machines, people work together to increase production tempo by 30%. Precise, flexible, fast and efficient delivery position can meet the needs of mass production.

In addition, the opening and packing system uses graphic programming, employees can master the operation method after simple training, so that employees say goodbye to heavy manual labor, focus on more valuable production process.

Program characteristics

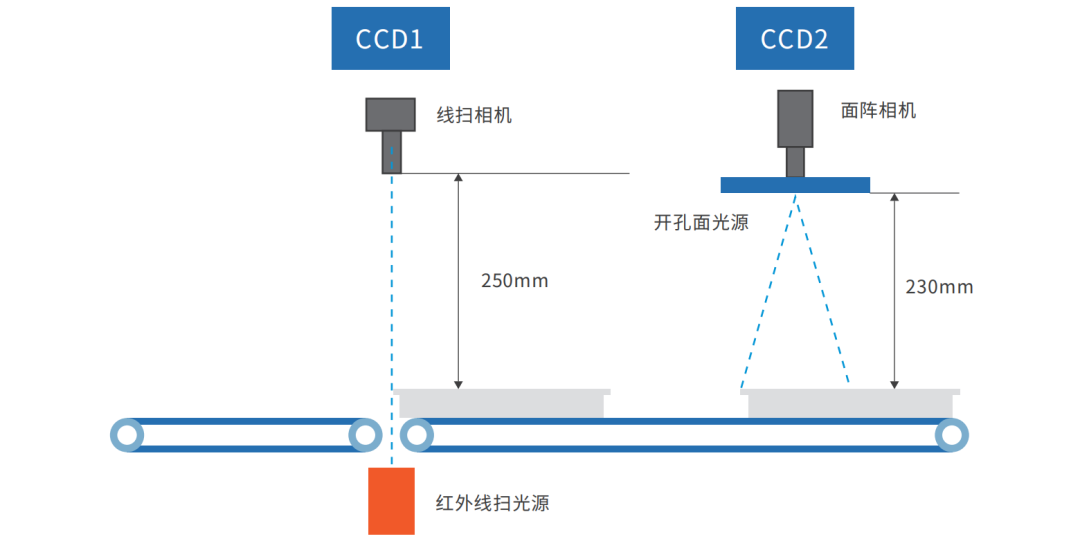

Visual inspection of air conditioning package

AI deep learning detection algorithm is combined with traditional visual algorithm for detection, which is mainly used to detect the quality of food packaging and eliminate defective products. The equipment can accurately detect foreign bodies (all kinds of hair, etc.) on the edge of food boxes.

At the same time, it has a higher detection accuracy for the diversity and inconsistency of defective parts such as the character and pattern changes of the label paper on the surface of the food box and the reading of one-dimensional code, and the missing detection rate is less than 0.01%.

SRT (SFG series) flexible jaw

The grasping action of the flexible claw is similar to that of the human finger, which is flexible and can automatically wrap the product, and can completely replace the hand to complete the grasping action. Its good compatibility, many categories, gentle action, suitable for most special-shaped, fragile items grab.

One - line automatic folding and sealing machine

The equipment can automatically replace the top cover of the carton and seal the carton with the upper and lower "one" font. It is suitable for the batch sealing production of multi-specification cartons. High degree of automation, using two sides of the drive belt automatic correction, smooth running, adapt to heavy load and easy to operate.

Automatic folding of carton cover, quick flat pressing without folding; The width and height can be adjusted manually according to the carton specifications, which can be completed quickly within one minute. The sealing box is firm and beautiful, saving labor costs and improving production efficiency. Can not only single operation, also can be used with automatic packaging machinery series.

If you want to explore with SRT

New opportunities for industrial change

From April 12 to April 14

Come and clock in at the SRT booth