This year, a thermos cup head company used 5 sets of Brocade (SRT) visual marking equipment for the bottom of the cup marking, achieving the following benefits:

Say goodbye to the separate manual work, optimize the manual and improve the accuracy;

Achieve single-machine production capacity of 1125pcs/h, single-shift production capacity of more than 9000;

Compatible with a variety of cup bottom automatic laser marking.

From traditional labor to automation

Make the operation more accurate and efficient, save time and effort

The thermos cup industry has always adopted the traditional manual marking method, which requires workers to align the thermos cup handle in advance and then mark it. According to statistics, manual and traditional equipment marking single-shift production capacity of 3000-4000, not only low efficiency, and there are errors, resulting in a decline in accuracy.

With the continuous rise of labor costs, while actively responding to the needs of national intelligent manufacturing and energy saving, a large number of thermos cup manufacturers began to move from the traditional manual marking method to advanced visual guidance laser marking technology to complete the automatic transformation and upgrading of the marking production line.

Machine vision laser marking technology

The new combination creates a new situation of bidding

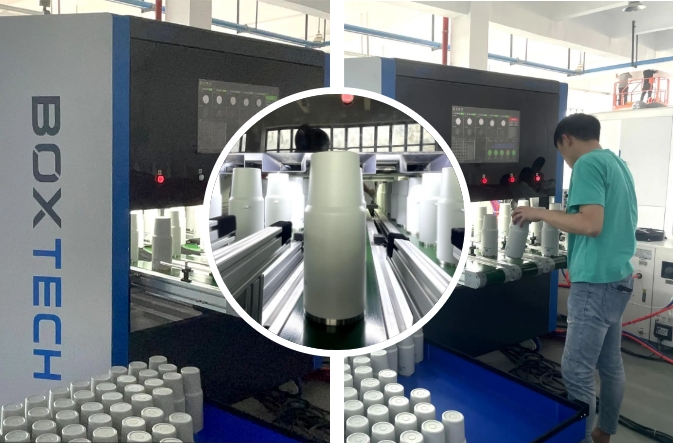

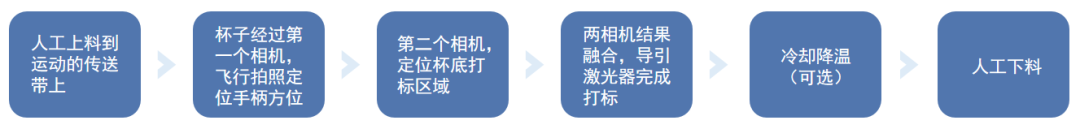

Visual marking workstation is mainly used in automatic guided laser marking on the body and bottom of the thermos cup to achieve connected operation and improve information management ability. Compatible with fiber laser marking, carbon dioxide laser marking.

【↑ Five channels parallel standards to quickly improve production output ↑】

Reasons to choose automatic marking

Maximize the value of customer benefits

Reduction in personnel

Labor saving, time cost controllable

NO.1 requires no manual matchup

The equipment adopts machine vision flight photo positioning, multi-channel parallel marking, helping customers to reduce 1-3 people in a single shift, with an accuracy of more than 99.7%;

synergism

Improve production efficiency and increase capacity

NO.1 Visual marking accurate positioning

The processing heat influence is small, the positioning is accurate, there will be no false, crooked, uneven, missing, gelling and other marking defects, improve product yield and product quality;

NO.2 Strong compatibility Applicable to all kinds of thermos cups

Visual marking workstation can be compatible with a variety of colors, cup marking tasks, and has an intelligent formula management system, can achieve one-click type change, save manual debugging time;

NO.3 Small floor area more cramped space available

Control the working area of the factory, from the original manual operation of 18㎡ to 6㎡, saving space;

NO.4 Data visualization information management

Relying on digital Kanban, the marking content quality inspection and report statistics are realized. Compared with the difficult management and traceability of manual marking in the past, the information management of visual workstations has promoted the high-quality production and manufacturing of factory floor products. At the same time, through the visual workstation docking MES and other enterprise information systems, to achieve fine management.

In addition, the visual marking workstation can be connected with the existing production line of the workshop to form a complete cup body and cup bottom marking line, which not only saves the time cost of manual frequent transfer, but also helps the enterprise to complete the automatic transformation and upgrading of the existing production line. Production line deployment can also be customized according to the different needs of the enterprise for capacity, single channel, double channel or multi-channel parallel production mode.