The 110th CHINA FOOD & DRINKS FAIR (hereinafter referred to as "FOOD & DRINKS FAIR") opened in the morning of March 20th in Chengdu, China West International Expo City. As an old friend of the previous FOOD & DRINKS FAIR, in this exhibition, SRT deeply focused on the field of packaging, bringing a new and upgraded version of the "mobile robot application platform" exhibition, and discussed modular automation technology with food industry insiders, helping the food packaging industry to develop in a smarter, more economical and more efficient direction.

Basic Information

【Development Time】March 20-22, 2024

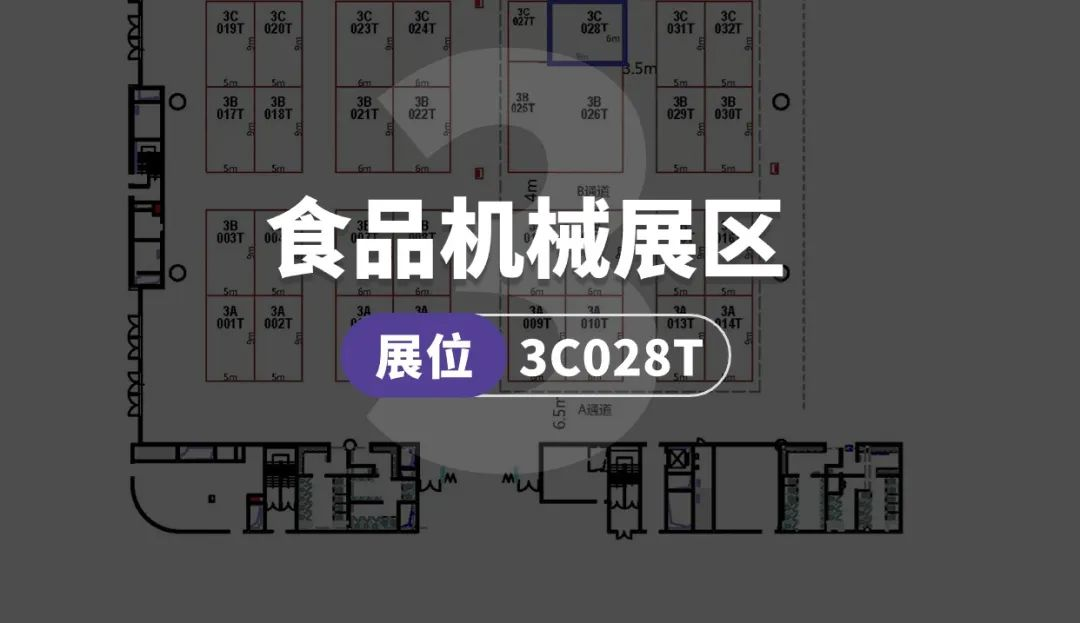

【Booth Location】Hall 3, 3C028T

【Display Scheme】SRT load moving robot application platform

SRT“Bionic family”Product module

【Map Marker】West China International Expo City (Chengdu)

Exhibition Background

FOOD & DRINKS FAIR is a long-established, large-scale and far-reaching exhibition in China's food industry. Since SRT's inception, soft robotics has been inextricably linked to the food industry. From the front end of food production, to the back end of product packaging, and finally to the business end of innovative applications, SRT products and solutions can leverage the technical advantages of most processes in the food industry.

At present, the improvement of residents' consumption level and the change of food consumption demand are driving the rapid growth of the food industry, forcing food manufacturers to "run" and move towards the direction of full automation, information and intelligence. However, this revolutionary change is already taking place quietly in the packaging industry.

Innovative solutions are updated and released

In 2023, in order to break through the constraints of the packaging industry with many product types, related product characteristics, packaging materials, and large differences in customer requirements, SRT makes full use of technical advantages to open up the "breakpoint" of the process, and successfully launched the SRT load shifting robot application platform, which will integrate the originally dispersed packaging line and help customers in the packaging industry realize the automatic production line upgrade.

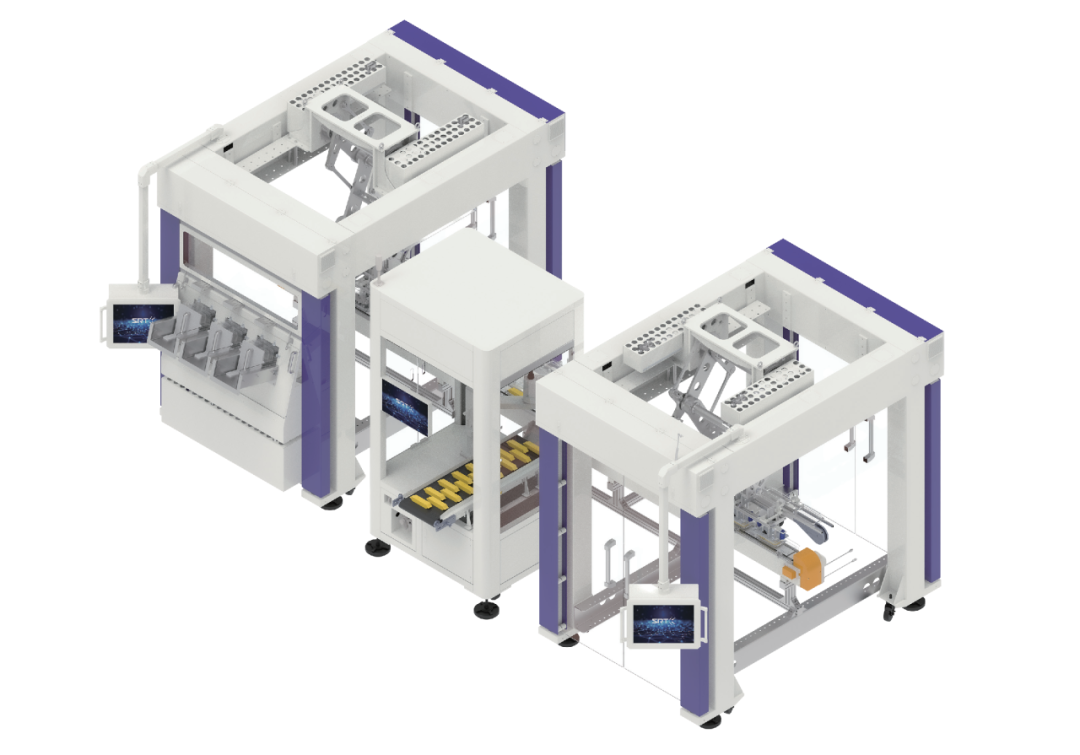

In 2024, through long-term field verification, SRT has carried out a comprehensive iterative upgrade of the SRT loading robot application platform on the basis of continuous collection of new needs, becoming a new generation of integrated packaging application platform with simple freedom, medium and high load, flexibility, standardization, and compatibility with a variety of material handling unit mechanisms.

Product Structure

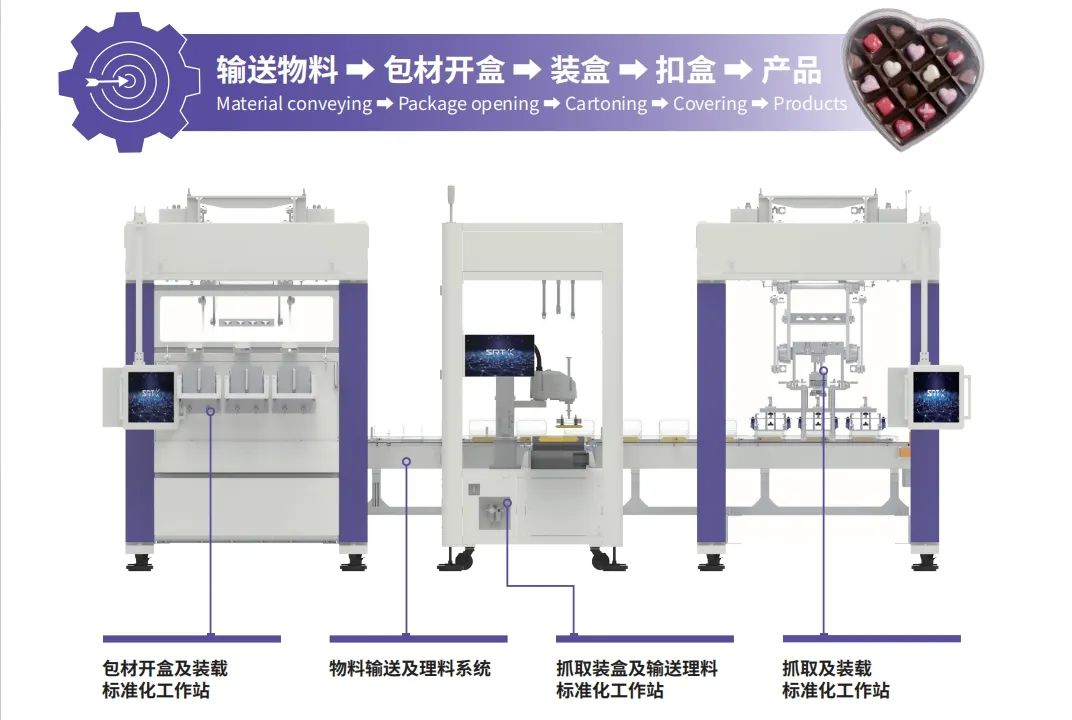

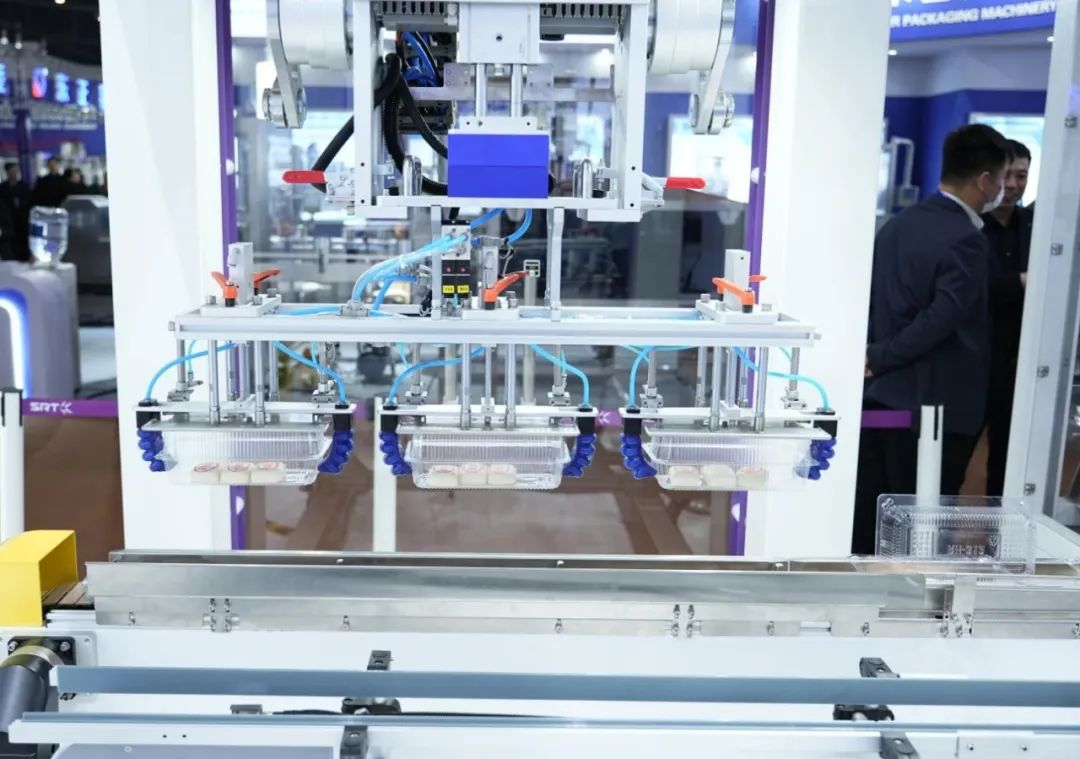

The upgraded SRT loading robot application platform is composed of four parts, including packaging material opening and loading standardization workstation, material handling and material management system, grabbing and loading standardization workstation, and handling and loading standardization workstation.

The platform adopts modular design, and the single machine is closely connected into an automatic production line, which realizes the fully automated operation of packaging material opening and loading, outer packaging box/box conveying, material location detection and grasping, box filling and box covering, and the production beat is ≥20 times/minute.

功能介绍

Packaging materials opening and loading standardization workstation is mainly used in the application of packaging materials, through the two axis and three axis robot cooperate with the opening of the box, and finally put the box on the conveyor line. Its main features are reflected in the multiple sets of gripper mechanism to adapt to a variety of materials, simple to use, the standardized design of the whole machine, but also can be installed to achieve material conveying, lifting, load shifting and other functions of the mechanism equipment.

The material handling and material management system connects each workstation in series through the conveyor line to complete the opening, filling, closing and product output.

The standardization workstation for grasping, packing and conveying materials relies on multiple sets of grasping mechanisms of different structures to complete the grasping work of different materials. Another advantage is the combination of AI deep learning detection algorithm and traditional vision algorithm for detection, mainly used to detect the location of materials placed on the conveyor line.

The grabbing and loading standardization workstation is an automated platform for the packaging of finished materials, using a two-axis robot to complete the capping, load shifting, and output the finished product.

Product advantage

In terms of material grabbing, the load shifting robot is equipped with multiple sets of gripper mechanisms of different structures, and adopts SFG flexible gripper independently developed by SRT to carry out grasping and load shifting operations. Flexible claw compatibility is strong, can adapt to a variety of material types and packaging material specifications; With quick change device to meet a variety of manual and automatic loading and unloading needs.

In terms of workshop deployment, the SRT load shifting robot application platform occupies only 3.1*5.7m of space, of which each single machine is standardized design, small structure, can be placed in a suitable station after a variety of combinations according to the actual production process needs, complete the layout of automated production lines, so as to meet the needs of various mass production.

In man-machine cooperation, the design follows the ergonomic principle, can reduce labor intensity, reduce fatigue, and each institution is equipped with safety protection devices; In addition, the selection menu mode of process formula allows employees to master the operation method after simple training.

In terms of comprehensive efficiency, the platform ADAPTS to the integrated and automated production line for various packaging needs, which can basically replace manual production and ensure 24-hour uninterrupted production of the production line; Compared with the manual production line, while saving part of the labor, the production efficiency is effectively increased by more than 30%; Working with people, the production tempo can be increased by 30%.

Overall, the new generation SRT mobile robot application platform can maximize the needs of different product characteristics, packaging materials and customers in a variety of industries. For example, in the food industry, the platform is suitable for one-time packaging (vegetables and fruits, meat and eggs, aquatic products, etc.), secondary packaging (drinks, dairy products, etc.); In the non-food industry, the platform is suitable for products such as daily chemical care, stationery toys, thermos cups, hardware and other products that need to be packaged.