As the world's largest semiconductor diode market, China has a huge demand for diodes.

A diode is a widely used electronic device made of semiconductor materials, which has unidirectional conductivity. Especially in various electronic circuits, the use of diodes and resistors, capacitors, inductors and other components are reasonably connected to form circuits with different functions, which can achieve AC rectification, modulation signal detection, limiting, clamping, and voltage regulation of the power supply voltage and other functions.

Whether it is a common radio circuit, or in other household appliances or industrial control circuits, traces of diodes can be found.

Production shackle

In recent years, the consolidation of China's semiconductor industry has been increasing, and the market concentration of the domestic diode industry has gradually increased. Mr. Wang, from an automation equipment and electronic components production enterprise in Xi 'an, grasped the good signal and wanted to upgrade the series automation of the diode production line.

In the conversation, we learned that the pain of Mr. Wang's enterprise is mainly focused on the detection and testing of light-emitting diodes. In China, the automation penetration rate of most diode manufacturers is low. After the light-emitting diode is packaged, it is also necessary to detect and test its brightness and light wavelength to ensure its yield and applicability. The vigorous development of the diode market in the front, the impact of the economic environment in the back, the dual factor game has accelerated the pace of enterprises want to improve flexible production.

New production application

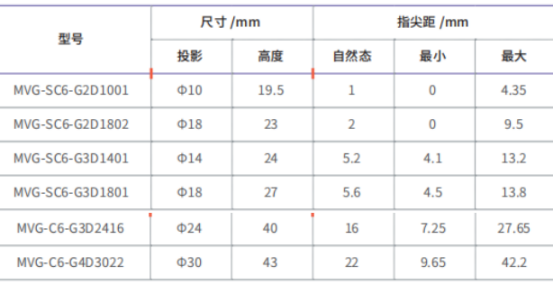

After detailed communication, Mr. Wang adopted the MVG micro vacuum clamp just launched by SRT, the model is MVG-G2D1001. He said that the diode is a small electronic component, in the grasp of the handling process, the electrode lead is not touched, the point of impact can only act on the shell.

The reason why the MVG micro vacuum clamp is selected is because it is flexible and compact, flexible operation, and can only grab the tube shell without touching the other parts of the diode, which meets the production needs of the diode.

In addition, Mr. Wang also mentioned that many end effectors on the market generally have the defect of stress concentration, which is easy to cause handling damage to the workpiece. The MVG micro vacuum clamp comes from the Soft Dexhand product family, which follows the soft robot technology based on the principle of bionics. The tensioning range is large and there is no stress concentration, which can protect the clamping part of the workpiece.

Record high efficiency

Mr. Wang's feedback focused on two areas. In terms of production efficiency, use the MVG micro vacuum clamp to accurately pick up the LED tube shell, and then put it on the test bench, hold the position for one or two seconds, and finally move it to the corresponding tray/process according to the feedback result of the test bench. In this way, a single process is repeated, and the detection of 15 leds can be completed per minute.

From the point of economic benefit, the MVG micro vacuum clamp is not only convenient to use, but also very convenient to install, and can be plugged and played. When upgrading the original production line, there is no need to add too much cost, and only a little transformation of the production line can achieve the actual benefit of "low input and high output".

It is worth noting that MVG micro vacuum gripper can not only grab diodes, but also suitable for most small electronic components on the market, which is equivalent to purchasing a set of vacuum gripper, which can complete the clamping and handling of multi-size workpiece on the production line. In the future, MVG micro vacuum grippers will also release more advantages in multi-industry product lines.

# micro vacuum gripper # diode #Soft Dexhand #