There is a huge system of 3C electronics, automobile manufacturing, and food industry, and there is a large variety of flexible production needs in small batches. If there is really a Soft Dexhand with a very wide coverage, ask: Who can produce mobile phones today and pinch cakes tomorrow?

Today, the flexible grasp reproduces a new combination, the new SRT module grasp integrated solution, deeply integrates the advantages of modular guide rail and flexible end grasp system, providing a new choice of flexible and efficient automation for many industries! From now on, we will present the content of 6-8 issues from different industries and different types of Soft Dexhand.

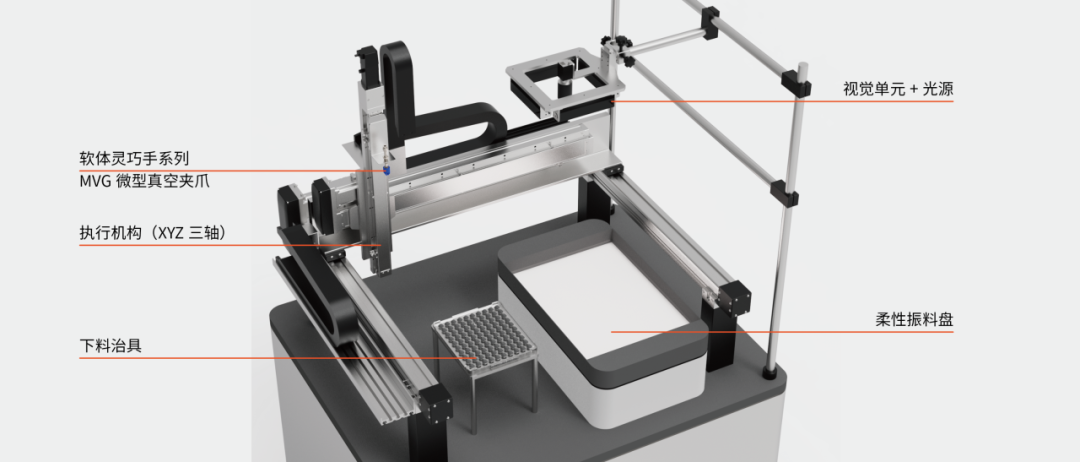

The SRT module grasping integrated solution cleverly combines modularity and flexible grasping, and the modular guide rail can realize linear movement in all directions in space through free combination.

The core of the flexible end grasping system is equipped with different products of the SRT smart hand series, which has high adaptability, not only to realize the non-destructive and non-trace grasping of precision parts in the 3C industry, but also to overcome the role of the last centimeter in the automated production of the food industry.

Integrated scheme of flexible sorting unit for small parts

The integrated solution of small parts flexible sorting unit is designed to meet the production needs of multi-variety, small batch and rapid transformation, especially for 3C, automotive and consumer electronics industries. Small components in these industries, such as welding springs, flat spring pads and small injection moulded parts, are often irregular and fragile, requiring efficient sorting. With the SRT Soft Dexhand series, it is possible to quickly change production, ensuring the flexibility and efficiency of the production line.

Technical highlights: Flexible configuration of intelligent worry-free

Three-axis linkage

XYZ axis collaborative operation, a wide range of travel coverage, flexible to cope with complex sorting paths;

Visual empowerment

With high-precision vision unit and light source, intelligent identification and positioning, greatly reducing the error rate;

Quick conversion

Flexible fixture fast switching, support multi-variety production, extreme compression change time.

Core advantage: modular + flexible dual-engine drive

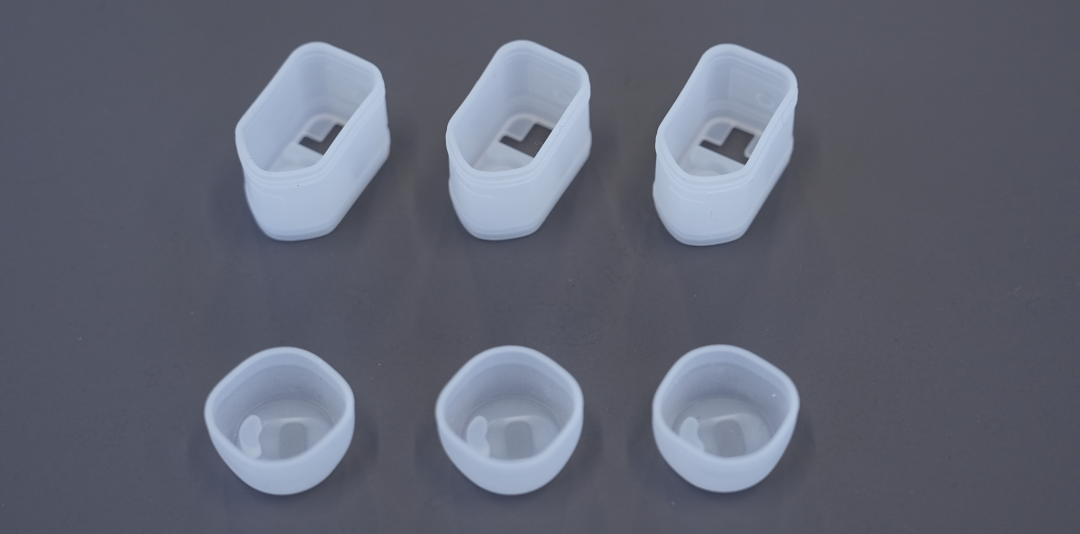

Workpiece | electronic cigarette silicone cap

Products | MVG Micro vacuum gripper (two fingers)

Method | cladding external grab, can be supported inside

Model number | MVG-G2D1802

The solution | electronic cigarette silicone cap weighs 20g, the inner wall is 15.8*12.8mm, the inner depth is 10mm; Wall thickness 2mm; The three-axis travel range is 600mm for X axis, 600mm for Y axis and 400mm for Z axis.

Modular guide

Free combination, multi-direction linear movement, easy to adapt to different production line layout;

Flexible end grab

SRT self-developed flexible grasping system based on software robot technology, adapt to irregular shape, achieve non-destructive and non-trace handling, precision parts, small shaped workpiece can be easily handled;

Efficient beat

0.8s high-speed beat, running speed 1m/s, load 2.5kg, productivity improvement is immediate.

Application scenario: Accurately adapt to multi-industry coverage

Question: What shape of workpiece does the grasping scheme adapt to?

Answer: SRT flexible end grabbing scheme is mainly suitable for needle, strip, square, cylinder, tower, cone and other irregular shapes.

Question: Which materials are the grasping solutions applicable to the workpiece?

Answer: The SRT flexible end grabbing scheme has strong versatility, in terms of workpiece material, such as plastic parts, hardware parts, ceramic parts, silicone parts, and other small composite parts can be grabbed.

Question: What industry artifacts does the capture solution cover?

Answer: The workpiece that can be grasped involves many industries such as 3C, automobile manufacturing, etc., the workpiece can be grasped specifically, such as spring, USB head, button, buckle, wire harness, gasket, connector, coil, O-ring, bottle cap, wire card, silicone cap, thimble, capacitor, joint, pin, bar, terminal, etc., which can realize high-precision non-destructive sorting. It can also meet the flexible production needs of multiple scenarios.