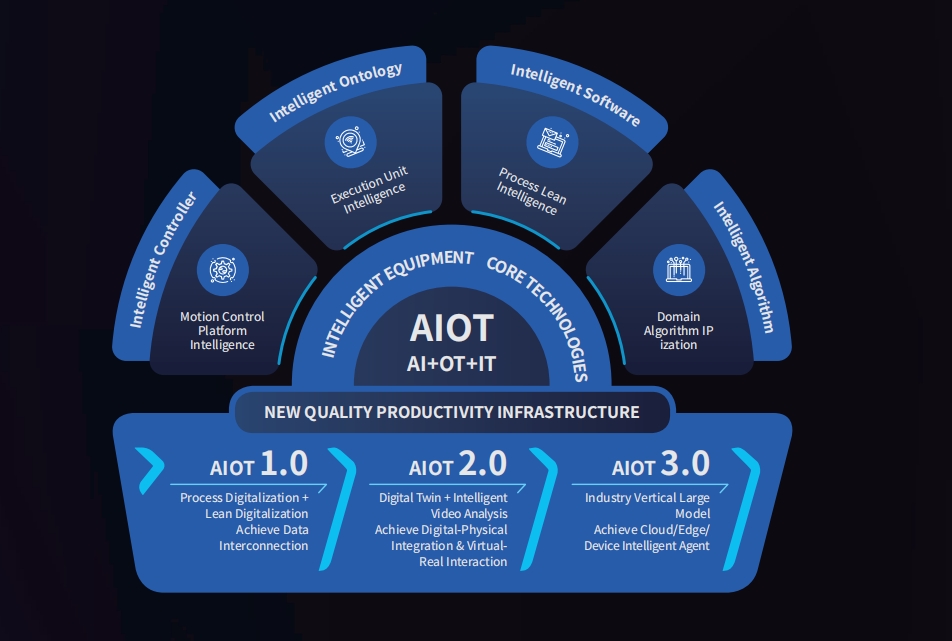

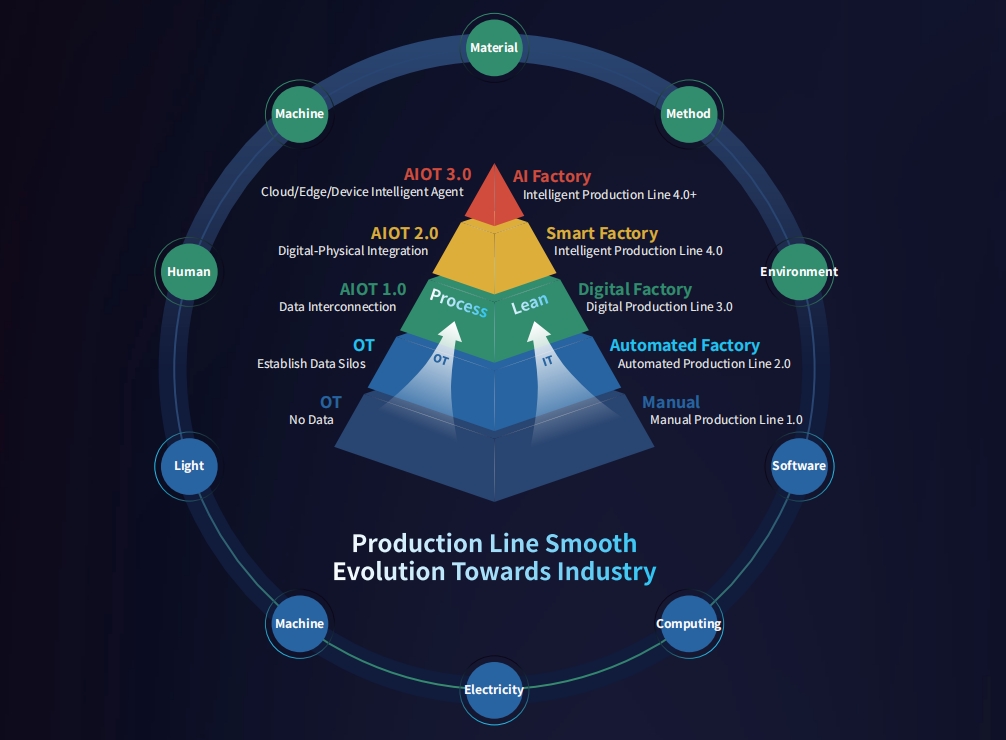

AI is an extension of human's "hands, eyes, and brain" intelligence capabilities. In the field of flexible manufacturing, SRT has achieved fruitful research and development results in areas such as intelligent execution (robots), intelligent perception (vision), and intelligent decision-making (BI). The core technology of the intelligent manufacturing of insulated cups is "light, machine, electricity, computing, software, process + lean", which promotes the progress of productivity through the continuous integration of OT and IT, and realizes the evolution and reshaping of the relationship between "people, machines, materials, methods, and environment" in the manufacturing industry. Boke Vision proposes that the core technology of industrial AI equipment is AI + OT + IT, which mainly includes four intelligent units: intelligent core, intelligent controller, intelligent software, and intelligent algorithm.

At the AFF conference, Boke Vision shared the existing AI implementation applications in digital factories, released the evolution plan of the intelligent production line of the insulated cup AI factory and the AI workshop solution for insulated cup manufacturing, and formulated a clear AI equipment and AIOT technology evolution plan to accelerate the smooth evolution of the production line of insulated cup manufacturing towards Industry 4.0, and promote the infrastructure construction of AI factories. With the strong support of the governments of Zhejiang Province and Yongkang City, SRT is accelerating the construction of AI factory infrastructure and creating a "cloud-edge-end" collaborative closed loop.

Four new intelligent equipment for the cup and mug industry were released, precisely focusing on the core pain points of the cup and mug industry, all equipped with industrial 4.0 software, installed with digital twin engine and intelligent video analysis engine, demonstrating the core strength of "AI innovation productivity".

Hot Shadow T7 - Intelligent Temperature Measurement Line 4.0

Leader of insulated cup intelligent temperature measurement

As the first industrial 4.0 demonstration production line in the industry, its core is equipped with the fourth-generation intelligent industrial management system, integrating digital twin and intelligent video analysis capabilities, precisely covering scenarios such as production line control, operation management, quality traceability, remote diagnosis, event focus tracking, and brand navigation.

The hot shadow thermometer also witnessed a breakthrough upgrade at the same time, innovatively applying blackbody technology, which can implement real-time temperature correction for thermal imaging cameras, effectively avoiding environmental interference, and significantly improving the standardization and consistency of equipment detection.

Rui Ying S7 - Appearance Inspection Machine

Guardian of high-quality polishing and spraying of insulated cups

Rui Ying S7 has achieved five breakthroughs in the industry:

The first appearance inspection equipment with extreme flexibility and the highest precision;

The first industrial 4.0 equipment that deeply applies digital twin technology;

Leading in formulating the first "Optical Inspection System Standard for Insulated Cup Appearance Defects";

First to launch an advanced high-speed 360° flying-shot detection system for curved surfaces;

First to launch an advanced high-speed flying-shot detection system for the surface of full-color products;

The core advantage of this product lies in integrating digital twin, quality data visualization, process knowledge base, and intelligent formula functions, significantly improving the digital level of insulated cup quality inspection and process management efficiency.

Precise Engraving M7 - Flexible Marking Workstation

All-round intelligent marking king for insulated cups

Precise Engraving M7 redefines the efficiency and flexibility of insulated cup marking with revolutionary breakthroughs:

Highly integrated production: Four-channel marking operations are highly integrated, covering all eight core marking business scenarios.

Intelligent process innovation: The industry's first "sequential marking" mode, combined with laser process digitization, realizes system one-click changeover, immediate production without debugging.

Quality precise guarantee: The first real-time torque monitoring technology, ensuring thread alignment accuracy within millimeters; equipped with a visual secondary composite alignment system to ensure zero error in marking position.

Clean and worry-free operation: Integrated with an efficient smoke removal and dust prevention system, completely eliminating residual marks from marking and achieving clean production without cleaning.

Precision Welding W7 - Intelligent Welding Integrated Machine

Thermal Cup Flexible Welding Pioneer

Precision Welding W7 has pioneered the "moldless welding" revolution with innovative integration of high-precision visual positioning and galvanometer laser technology. It is the first in the industry to integrate the double-process integration of the joint opening and welding joint. The equipment is fully compatible with mainstream welding processes such as straight joints and false arc joints, meeting diverse production needs. Relying on the deeply empowered AIOT 2.0 software platform, it integrates digital twin, process knowledge base and intelligent formula system. Precision Welding W7 is vigorously driving the digital upgrade of the welding field.