Compared with traditional function phones, smart phones are wildly sought after by the majority of consumers as soon as they are launched, which directly promotes the rapid development of smart phone market. Thanks to the strong rise of the mobile phone market, a number of upstream and downstream industrial chains have been driven to synergistic development, among which the VCM motor used for lens focusing is one of the industries to take advantage of the wind.

In the current situation of highly homogeneity of mobile phone system and appearance, major mobile phone manufacturers turn to the function of competing camera, opening the "arms race" of camera module, which directly affects the speed and accuracy of camera focusing VCM motor, market demand can be said to be further increased.

When the demand for VCM motor is increasing and the degree of precision is becoming higher and higher, related manufacturing enterprises are stepping into the era of automated production in order to maintain competitiveness and seize market opportunities. However, because of the small and precise attributes of VCM, the automatic transformation of the production line of the enterprise has brought no small problem: if the clamping force is too large, the motor may be squeezed out of shape, resulting in loss; If the force is too small, it may fall off during load shifting, reducing production efficiency.

How to achieve stable and efficient loading and unloading? SRT is a pioneer of advanced technology and a supplier of innovative products. It has been continuously digging into the industry demand, breaking through technical barriers, adhering to innovation, and launching ISC inner soft clamp, enabling the automation transformation of VCM motor manufacturing enterprises.

Flexible expansion 360 degrees seamless fit

Gentle "traceless" grasp

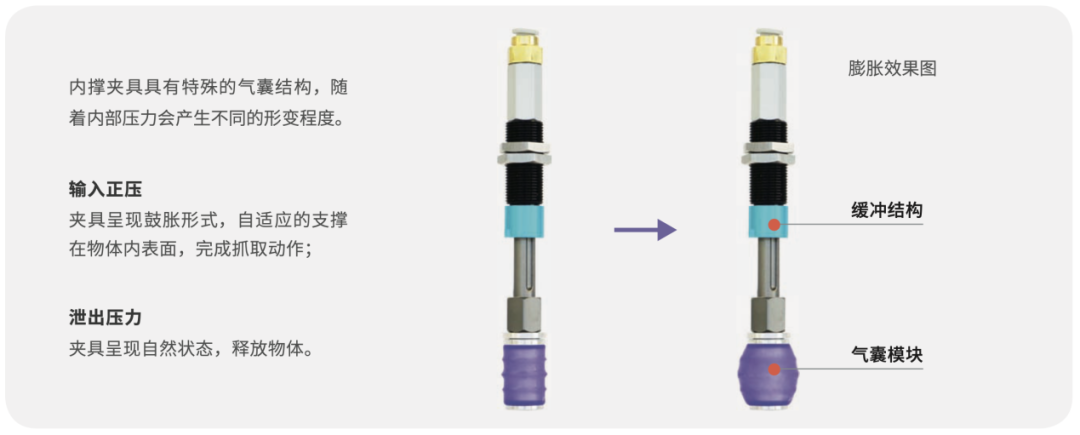

ISC inner soft clamp is an innovative flexible fixture that imitated the puffer fish self-defense form and bionic design. By filling the flexible air bag with a certain pressure, the air bag will expand like the puffer fish and complete the inner support grab. Compared with other conventional two-point, three-point internal support fixture, ISC inner soft clamp can achieve 360 degrees of seamless fitting of the workpiece, not only without stress concentration, will not deform the frame support, strength can also ensure that the workpiece will not fall in the process of grasping, ensure grasping efficiency.

In addition, ISC inner soft clamp is made of soft food grade silica gel material, pressurized and formed a layer of "air cushion" between the workpiece, flexible contact with the workpiece, to achieve no trace, non-destructive clamping or handling. Compared with traditional rigid fixture,ISC inner soft clamp is less likely to damage the workpiece.

High expansion rate

High adaptability

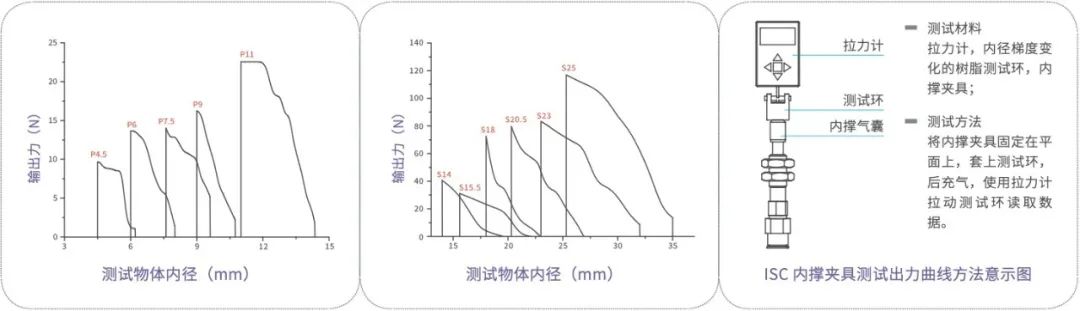

Besides and artifacts are flexible contact, the another advantage of flexible bag also lies in its high inflation rate, convenient control, filling the barometric pressure within the organization to adjust the amplitude of the airbag inflation pressure and contact workpiece size, so that the same type of fixture with different diameter of expansion in a certain range, can be compatible with a variety of different diameter of the workpiece, the fitment is higher, It also has a wider range of applications. Not only that, ISC air bag internal support fixture also has the characteristics of small volume, high flexibility, can quickly "flash" in a narrow space, the working environment is more adaptable, and the section size is small, it is easier to achieve high density array arrangement, so that the grasping efficiency is further improved.

【 Output curve 】

Note: The length of the above test connected trachea is 0.5m

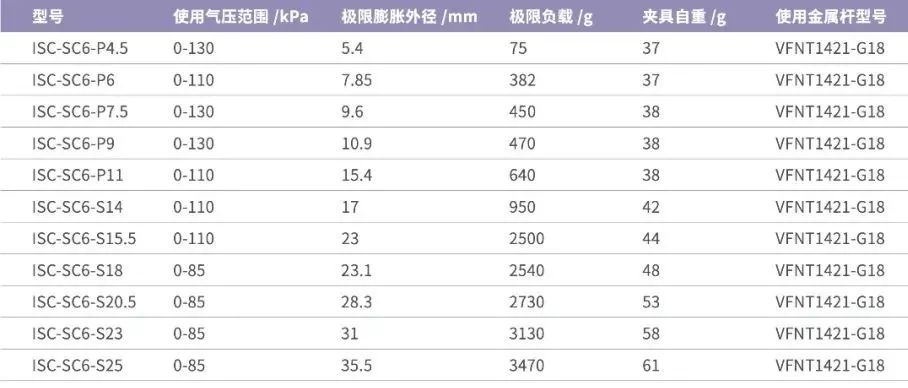

【 Expanded outer diameter 】

Note: P series limit load test object is model outer diameter +0.3mm; S series limit load test object model outer diameter +1mm; The load test was carried out by a professional instrument.

Customization service

Achieve a quick change of outfit

According to the requirements of enterprise automation transformation, SRT can customize a load shifting scheme more in line with the actual working conditions of enterprises, and quickly adapt and install the original production equipment. It is worth mentioning that, based on the characteristics of ISC inner soft clamp, which is convenient to use, easy to install plug and play, and can be adapted to most types of mechanical arms in the market, enterprises can also choose to directly replace the original end fixture on the production line with SRT customized airbag, which greatly reduces the work intensity and cost of transformation and daily maintenance. With the rapid development of the industry and the continuous improvement of user demand, automated production is not only the general trend, but also the guarantee of efficiency, yield and product quality. SRT provides flexible intelligent end-effector solutions for VCM motor enterprises with forward-looking and innovative technologies to meet their various demands for flexible production and help enterprises seize new opportunities and challenges in the new consumption era.